Comparison of MultiBio boilers and burners with other burners

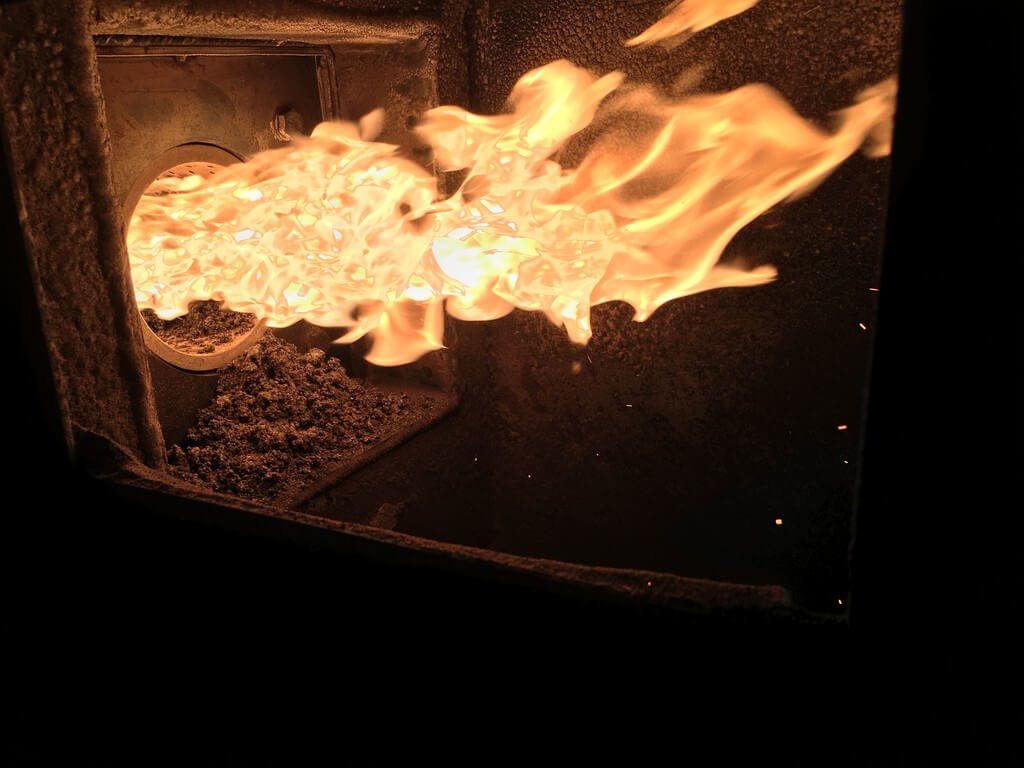

MultiBio Burners are able to burn fuel with difficulty combustible due to their construction, such as plant pellets.

MultiBio boilers are multi-fuel. These boilers excel in burning a wide variety of pellets, both wood and plant and their mixtures.

The advantage of combustion of plant pellets lies above all in their price. The price of vegetable pellets is up to half the price of wood pellets. MultiBio pellet boilers can also cope with the combustion of plant pellets made from highly sintered materials such as grain straw or hay thanks to MultiBio unique internal design.

MultiBio burners also have a great advantage in burning wood pellets.

Our customers often ask what are the advantages of a MultiBio rotary burner against bowl burners or square universal burners in connection with the burning of wood pellets. At first glance, it would seem that wood pellets can burn all types of burners on the market. MultiBio burners can also burn pellets whose quality does not match the certificate issued by the dealer to pellets. This is often the case and the pellet dealer can hardly prevent or influence it.

The primary advantage of the burner is that it is not susceptible to the quality of wood pellets and can burn even the lowest grade pellets that burn ash ash or even pellets that may contain more minerals and a significant amount of ash or admixtures that can make pellets easier for their producers production.

From experience, we know that even if you bought high quality pellets with a certificate, you may find that you have a batch that did not "do". Then there is a situation that you have, for example, 5 tons of pellets in the basement, which the "normal" burner can not burn. Even if the dealer of the poor pellet willingly exchanges, it is necessary to move them out of the cellar or suffer removing excessive ash, or clinkers from the burner and re-burn the burner. The MultiBio boiler does not do this. It can reliably burn pellets with which the normal burners or torch burners can not burn.